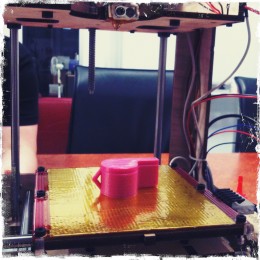

As our Thing-O-Matic comes closer to home, we have been putting together some preliminary considerations. While apparently it is possible to print using a 3D printer without having a computer directly attached, such as through the Make interface.

However, for the level of capacity we wish to offer artists, using a set interface may be a little too limiting. Therefore we are planning to attempt to hook up an eepc because an eepc has a solid state drive and therefore is much more portable than any other portable laptop. It is also possible in theory to use a smart phone but developing a schematic for a 3D object on a smart phone would seem problematic.

Software tools of choice; Our software tools of choice are blender and/or wings3D. These are two opensource products which are able to be used to produce the files required to print 3D objects. Wings3D is a more mathematically based application and also more limited by design than Blender.

As our tech officer has had a bit of experience in the past with dealing with 3D applications he decided to produce the following stamp. However the handle may be a little too complex and it might be best to start from scratch with blender instead of using wings3D.

3D Scanning

We are also looking into the ability to scan, modify and print physical objects, giving artists the ability to literally use the world around them to assist in the implementation of their own artistic ideas. We are considering a technology like DAVID as it’s simplicity makes it easy to understand and affordable.

The requirements for the scanner is a web camera, two white walls or pieces of card depending on what you are scanning, a special type of lazer and the DAVID free software.